MES is a set of production information management system. Through the transmission of information, the entire process from order placement to product completion is optimized and managed, and real-time events occurring in the factory workshop are responded to and reported in a timely manner, and accurate data is used for guidance and processing. Realize the digitization, intelligence and visualization of the manufacturing process.

Application and introduction

MES is a set of production information management system. Through the transmission of information, the entire process from order placement to product completion is optimized and managed, and real-time events occurring in the factory workshop are responded to and reported in a timely manner, and accurate data is used for guidance and processing. Realize the digitization, intelligence and visualization of the manufacturing process.

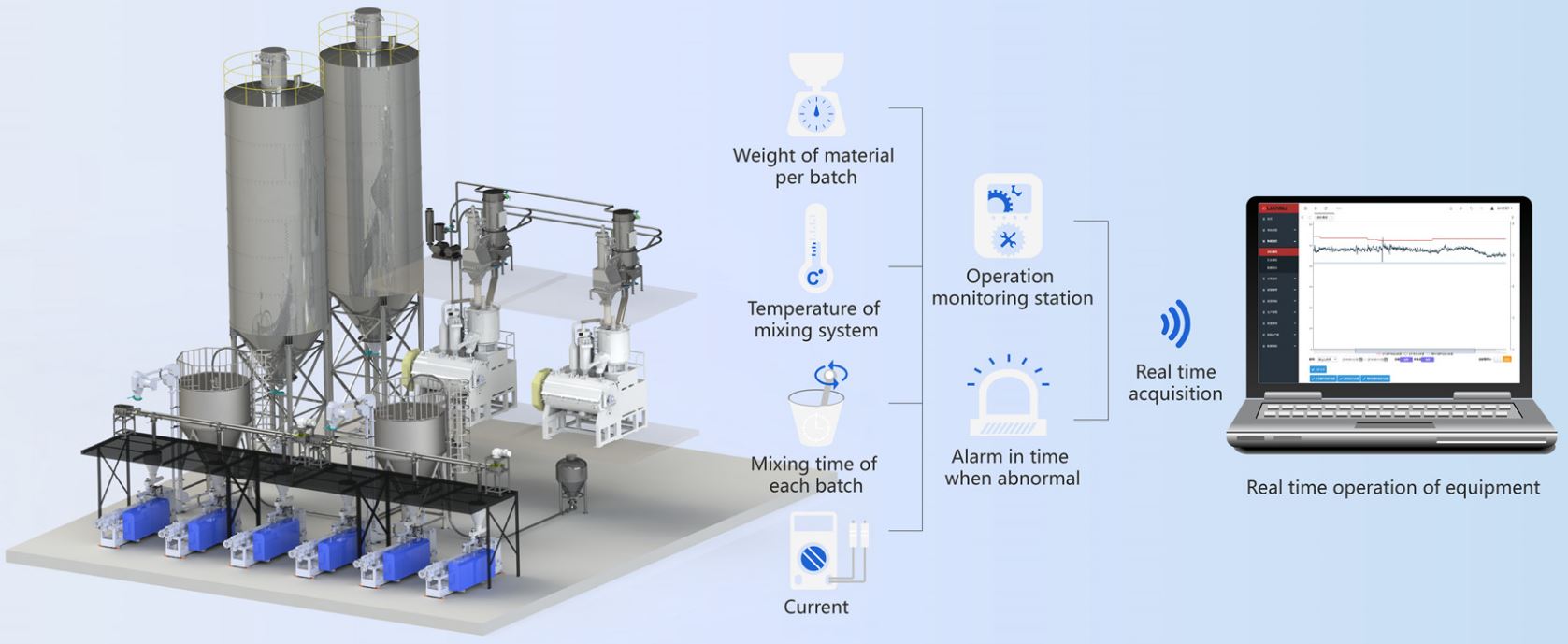

FEEDING DIGITIZATION

Equipment acquisition:Real time collection of mixing system temperature, current, mixing time of each batch, etc.

Operation monitoring:Each batch of mixing time monitoring, real-time monitoring of equipment status, and alarm in case of abnormality

Process visualization:Check the real-time operation of the equipment through computer and large screen board.

MANUFACTURING DIGITIZATION

Equipment acquisition:Real time acquisition of equipment process parameters, speed, quantity, material consumption, electricity consumption, etc.

Fault warning:Data analysis of unit power consumption, equipment utilization rate, daily output, shift output, product quality problem tracing, etc.