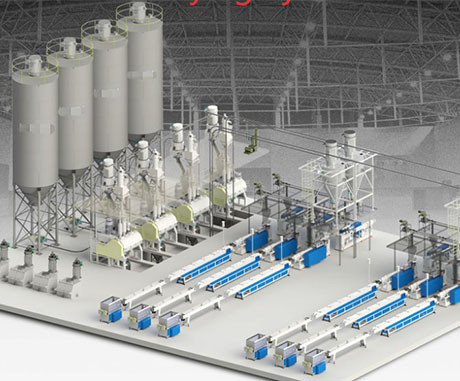

Mixing And Dosing System Introduction

The main function of the automatic batching system is to feed a variety of raw materials into their respective bins through the feeding system, and then add them to the electronic scales according to the ratio of raw materials given by the production formula, and then send them to the hot and cold mixer for mixing and stirring, and control the temperature of the material mixing and stirring accordingly to ensure the material is mixed evenly and the characteristics of the mixed material meet the requirements of the production process. Finally, the mixed material will be used in PVC foam board, foam pipe and profile production line.

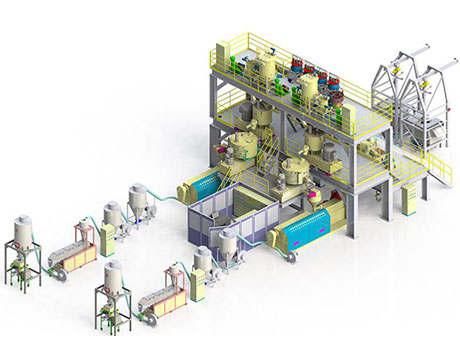

Working Principle

The automatic dosing system is a very important process in the production process of the fine chemical plant, and the quality of the dosing process is important for the quality of the whole product. The automatic batching control process is a multi-input and multi-output system, where each batching and conveying line is strictly coordinated and controlled, and the material level and flow rate are monitored and adjusted timely and accurately. The system is composed of programmable controller and electronic belt scale, which is a two-level computer control network, connected with field instrumentation, control computer, PLC, frequency converter and other equipment with high intelligence and fast processing speed through field bus. In the automatic batching production process, the main material and auxiliary material are matched in a certain proportion, and the electronic belt scale completes the measurement of the material conveyed by the belt conveyor; PLC mainly undertakes real-time control of the conveying equipment and weighing process, and completes the detection of system failure, display and alarm, while the output signal to the inverter regulates the speed of the belt machine.

Automatic Dosing System Features

● Real-time acquisition of weighing signals from each electronic scale load cell.

● Generates control signals for screw feeders, electronic scales valves, etc., according to the weighing signals and the production recipe.

● Lower unit communicates with the upper unit.

● Centralized monitoring by the upper computer.

In mixing and dosing, the weighing instrument collects the signal from the electronic scale weighing sensor, generates the control command of the actuator with the help of the raw material ratio given by the recipe, and controls the start-stop and opening/closing of the screw feeder, electronic scale valve and hot and cold mixer valve of each bin through the programmable controller; it gets the operation and fault situation of the motor and valve by detecting the motor protection device and valve position switch status, which can be displayed on the analog display operation screen of the electrical control cabinet or on the monitor of the upper computer.

Chiyu has been a leading manufacturer of high quality automated dosing systems, earning a worldwide reputation for excellence. Our dosing systems provide maximum capacity, efficiency and consistency by accurately weighing and transferring formulations to dosing silos. In addition, our other innovative equipment, such as large bag weighing units, screw conveyors, flexible screw conveyors, pneumatic conveying systems, raw material storage silos, liquid dosing units, hoppers, and automatic feeding systems, can further streamline your production process. Let's work together to save time, reduce waste, increase productivity, and achieve unparalleled results. Contact us today to learn more!