High speed mixer also know as heating mixer cause heat generated during mixing, it provide multiple components intensive distribution and mixing. Cooler also known as cooling mixer, used for cooling down hot material come from high speed mixer. Two mixer ( heating mixer and cooling mixer ) can work together or separately.

Heater and cooler mixer composed of one hot mixing pot and one cooling pot,the materials from hot mixer will be filled into the cooling mixer automatically, so it can eliminate humidity, and protect from agglomeration.

The high speed heater cooler mixing system is characterized by excellent product preparation capacity and efficient cooling performance during the heating phase.

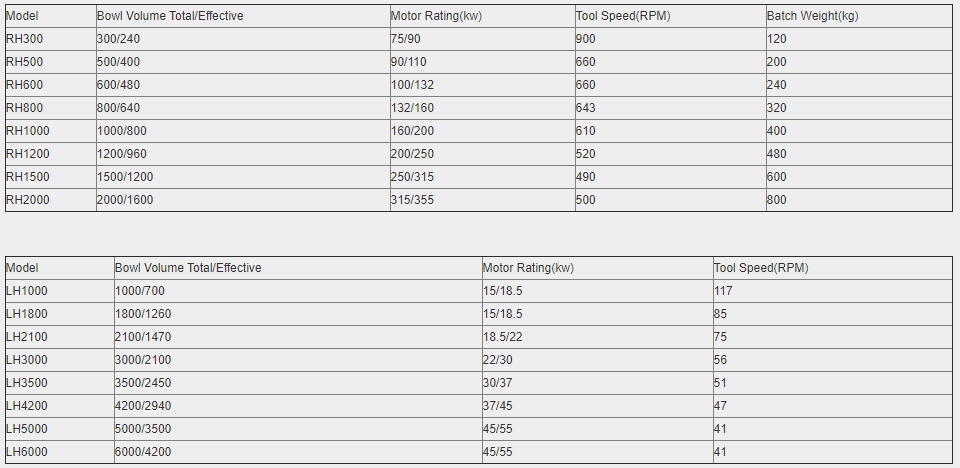

There are two main types of high speed heater cooler mixers: vertical heater cooler mixers and horizontal heater cooler mixers. Next, their main features will be described

High-performance cooling with three cooling zones enables particularly gentle mixing and efficient cooling of the material.

High speed mixer also know as heating mixer cause heat generated during mixing.it provide multiple components intensive distribution and mixing. Cooler also known as cooling mixer, used for cooling down hot material come from high speed mixer. Two mixer can work together or separately.

It is suitable for mixing, coloring and drying of powder and granular materials in plastic, rubber, chemical and food industries. It is typically used in PVC plastic products, plastic modification, material mixing before extrusion and granulation, and multi-component powder mixing before wood plastic products production.

1.Alt material in contact with product Is in SS304 or aluminum alloy and the product will not be contaminated.

2. High cooling efficiency, short mixing time. easy and convenient to clean.and can reach high output

3. Improved cooling efficiency and reduced water consumption.

4. Mixing tool can be designed according to different application.