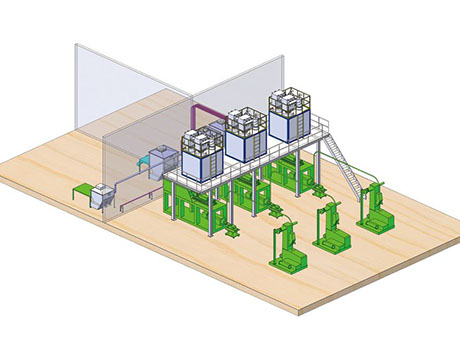

Rubber products production line with kneader mixer is designed for all kind of rubber products which requires single stage or multi-stage mixing process. The production line mainly contains Automatic Multi-ingredient Formula Weighing System,Kneader mixer,Bucket elevator ,Rubber open mill ,batch-off etc.

Rubber Products Production Line with Kneader mixer

Rubber products production line with kneader mixer is designed for all kind of rubber products which requires single stage or multi-stage mixing process. The production line mainly contains Automatic Multi-ingredient Formula Weighing System,Kneader mixer,Bucket elevator ,Rubber open mill ,batch-off etc.

Main Technical Parameters:

| Powder scale weighing range | ≤200 Kgs |

| Oil scale weighing range | 1-50 Kgs |

| Powder weighing accuracy | Static≤±0.1% F.S, dynamic:±0.1--±0.5Kg. |

| Oil weighing accuracy | Static≤±0.1% F.S, dynamic:±0.1--±0.5Kg. |

| Conveying capacity | 1-1500Kg/h |

| Transmission distance | Horizon≤80m; Vertical≤20m |

| Pipe diameter | DN50-100 |

| Air source | Root's Blower |

Features:

Δ This system is suitable for banbury capacity from 55L to 160L

Δ It is applicable for the factory building structured of 1-storyey or 2-storey, saving the construction cost for new factory building

Δ This system is to fulfill the storage, conveyance, weighing and dosing of the major ingredients, such as carbon black, white fillers, and oils

Δ The storage area are separated from the production area

Δ This system had integrated mixer upstream equipment, banbury, rubber scale in one program, and realize the online control

Δ This system is realized the production automation and management information systemization

Δ This system mainly applicable for production of rubber products, plastic products, shoes, rubber cable materials, chemical materials…

Δ This system had combined vacuum type conveying and screw type weighing, less space occupancy (1-2 meters higher than full vacuum system) and high weighing accuracy(+/- 50g-0.5%).