Copyright © 2021 Zhangjiagang ChiYu Automation Equipment Co., Ltd. by iwonder.cn All rights reserved. Site Map

Pneumatic conveying systems have become a cornerstone in many industries, particularly in food processing. These systems allow for the efficient, reliable, and sanitary transport of materials, reducing labor costs and improving overall operational efficiency. In the case of sugar processing and handling, pneumatic conveying systems provide a host of benefits, from faster production times to enhanced product quality. In this article, we will explore how sugar pneumatic conveying systems work and the ways they improve efficiency in food processing.

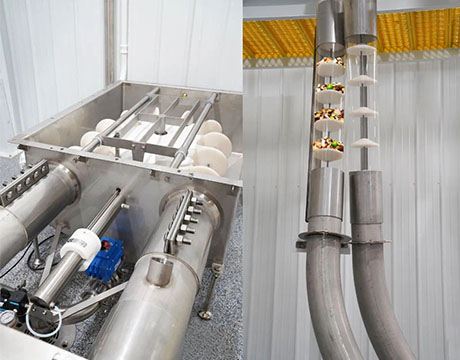

Pneumatic conveying systems use air or gas to transport bulk materials through pipes. Unlike mechanical systems, which rely on physical moving parts like belts or conveyors, pneumatic systems use pressure or vacuum to push or pull materials through a closed pipeline. This makes them highly versatile, as they can handle a wide range of substances, from powders to granules, in various industries, including food, pharmaceuticals, and chemicals.

In the context of sugar processing, pneumatic conveying systems are employed to transport sugar in various forms—whether granulated, powdered, or even liquid—across different stages of production and packaging. These systems ensure that the sugar reaches its destination quickly, safely, and without contamination.

Sugar pneumatic conveying systems are typically designed to handle both light and dense sugar particles with high precision. The system can be divided into two main types: positive pressure and vacuum-based systems.

Positive Pressure Systems

Positive pressure pneumatic conveying systems work by blowing air into the system, creating a pressurized environment that pushes sugar through pipelines. This type of system is commonly used when the conveying distance is relatively short and when a consistent, high-speed flow of material is required. The material enters the system through an inlet, where it is picked up by air and transported through the pipeline to its desired location.

Vacuum-based Systems

On the other hand, vacuum-based pneumatic conveying systems use suction to pull the sugar through the pipeline. This system is ideal when sugar needs to be conveyed over longer distances or in situations where delicate handling is required. Vacuum systems minimize the risk of sugar particles breaking, clumping, or being contaminated.

Both types of systems can be customized depending on the specific needs of the food processing facility, including factors such as the sugar’s form, the distance it needs to travel, and the required speed.

Sugar pneumatic conveying systems have revolutionized how sugar is transported in food processing, offering significant improvements over traditional methods. Below are some of the key benefits:

1. Improved Speed and Efficiency

One of the primary advantages of pneumatic conveying is speed. Conveyor belts or manual handling systems can be slow, especially when moving large quantities of sugar across a facility. Pneumatic systems, by contrast, can quickly move materials over long distances without the need for manual labor or frequent stops for maintenance. This increase in speed results in higher throughput and greater overall operational efficiency.

With the right pneumatic system in place, sugar can be transferred between various stages of production, such as from storage silos to mixing machines, packaging lines, or even directly to trucks for shipment, all with minimal downtime.

2. Reduced Labor Costs

The automation provided by pneumatic conveying systems reduces the need for manual labor. Traditionally, moving sugar from one location to another required workers to carry or shovel large amounts of material. This not only required significant labor resources but also increased the risk of injury. Pneumatic systems eliminate this need, saving both time and money by reducing labor costs.

Moreover, automation improves consistency in the process, ensuring that the correct amount of sugar is transported without errors, thereby reducing human error and enhancing accuracy.

3. Improved Product Quality and Hygiene

In food processing, hygiene is of utmost importance. Contaminated sugar can lead to quality issues and potential health hazards. Pneumatic conveying systems are fully enclosed, which helps maintain the cleanliness of the sugar as it travels through the system. Unlike open conveyors, which expose the product to dust, dirt, or even pests, pneumatic systems minimize the risk of contamination by protecting the sugar from external elements.

Additionally, pneumatic conveying systems often come equipped with filters or cyclones that help separate and remove any airborne contaminants from the sugar. This is particularly beneficial when handling highly sensitive products such as powdered sugar, which can attract moisture or other impurities more easily.

4. Minimized Product Waste and Loss

Sugar is an expensive commodity, and minimizing waste is critical to maintaining profitability. Traditional mechanical conveying systems often suffer from material spillage or loss due to leaks, spills, or inefficient handling. Pneumatic conveying systems, however, are highly controlled and tightly sealed, reducing the chances of sugar being lost or wasted during transportation.

The accuracy of pneumatic systems ensures that the right amount of sugar is delivered to each stage of processing, reducing overflows and under-delivery, both of which can be costly.

5. Energy Efficiency

While pneumatic conveying systems require energy to operate, they are generally more energy-efficient compared to traditional mechanical systems. This is because pneumatic systems can be tailored to operate at the ideal pressure or vacuum levels necessary to move the sugar efficiently. Energy consumption can be further optimized by using advanced sensors and control systems that adjust the airflow based on the amount of material being conveyed.

Moreover, pneumatic systems typically require less maintenance than mechanical systems, as they have fewer moving parts, which reduces long-term operating costs.

Sugar pneumatic conveying systems find use in various areas of food processing, from raw material handling to packaging. Some common applications include:

1. Bulk Handling of Sugar

In large-scale sugar refineries or production facilities, pneumatic conveying systems are used to transport raw sugar from storage bins or silos to processing units. This process must be highly efficient, as delays or contamination can affect production schedules. Pneumatic systems ensure a continuous and smooth flow of material, preventing bottlenecks and maintaining consistency.

2. Sugar Transfer to Mixing or Blending Equipment

In the production of certain food products, sugar must be blended with other ingredients such as flour, cocoa, or flavorings. Pneumatic systems transport sugar directly to mixing or blending equipment, ensuring that the sugar is properly integrated with the other ingredients in a hygienic and efficient manner.

3. Sugar Packaging

Pneumatic conveying is also used in the final stages of food production, particularly when packaging sugar for distribution. Automated packaging systems rely on pneumatic conveyors to move sugar into bags, boxes, or containers at high speeds, reducing the need for manual labor and ensuring a consistent, high-quality product.

Sugar pneumatic conveying systems play a pivotal role in improving the efficiency and productivity of food processing facilities. By automating the transport of sugar, these systems not only save time and reduce labor costs but also ensure better product quality, minimize waste, and increase overall throughput. With their ability to enhance hygiene and reduce energy consumption, pneumatic conveying systems represent a forward-thinking solution for modern food processing operations. As demand for more efficient and sustainable food production processes grows, pneumatic conveying will continue to be a key player in transforming the sugar handling industry.