Copyright © 2021 Zhangjiagang ChiYu Automation Equipment Co., Ltd. by iwonder.cn All rights reserved. Site Map

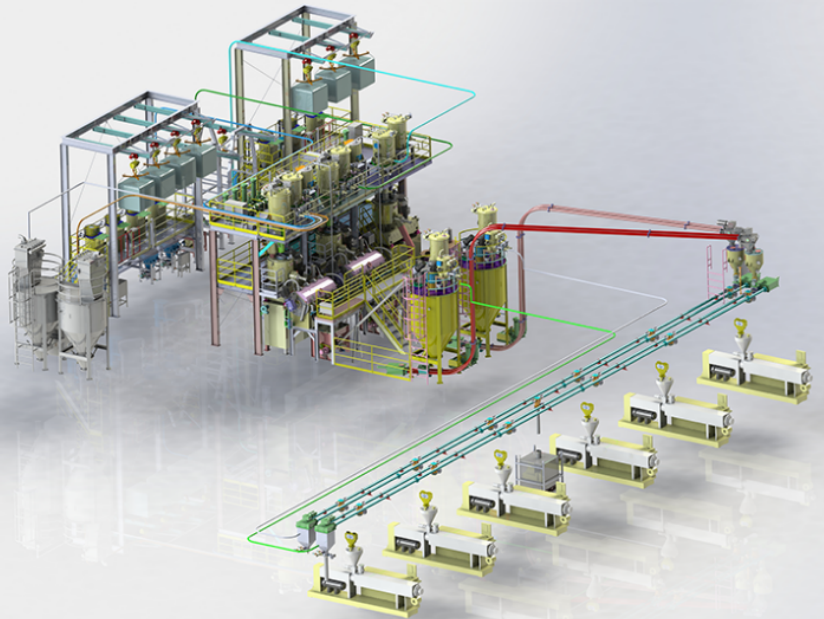

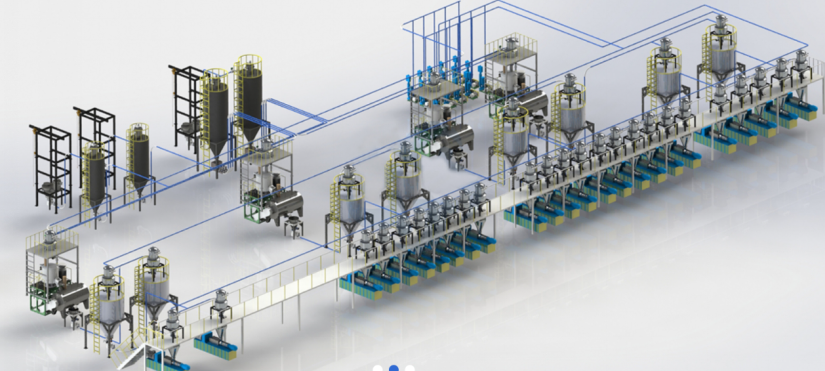

ChiYu’s combined heating/cooling mixers are the optimum solution for complex mixing challenges. The systems are characterized by their outstanding product preparation in the heating phase and high-efficiency cooling performance. The horizontal and vertical heating/cooling mixers are designed for high-volume throughput, rapid processing and short cleaning times

The vertical cooling mixer is an economical, robust solution for throughput volumes up to 2,500 kg/h. A high-performance multi-stage mixing tool in the heating mixer generates friction to heat the product. At the same time, all recipe ingredients are evenly distributed throughout the mixture. When the desired target temperature has been reached, the mixture is transferred to the cooling mixer through the discharge port and the heating mixer is ready for the next batch.

The material is cooled in the vertical cooling mixer by passing it gently across a cooled surface several times. An optimum cooling performance is achieved through targeted water circulation in the mixer floor and sidewall.

The cooled mixture can then be emptied rapidly via the dead-space free discharge port.

1.Can be used for a wide range of different applications e.g. heating, agglomerating, bonding

2.Process-optimized mixing tools guarantee optimum energy input

3.Selection of performance-optimized mixing drives for high energy efficiency

4.Innovative aspiration for optimum dehumidification of the mixture

5.Wide range of optional accessories allows ideal adaptation to installation space requirements

6.ATEX version possible

7.Most economical solution for throughput volumes up to 2,500 kg/h

8.Mixer lid opens for fast, easy cleaning

9.Optimum water circulation in mixer floor and sidewall for high-performance cooling

The combination with a horizontal cooling mixer is the perfect solution for high-performance applications requiring larger throughput volumes. High-performance cooling with three cooling zones enables particularly gentle mixing and efficient cooling of the material.

A multi-stage mixing tool in the heating mixer heats the product and distributes all recipe ingredients and materials evenly throughout the mixture. When the desired target temperature has been reached, the mixture is transferred to the cooling mixer through the discharge port and the heating mixer is ready for the next batch.

The specifically configured water circulation system in the horizontal cooling mixer ensures the best possible cooling performance in the three cooling zones. Besides the relatively large cooling area, the optimum water circulation speed is another factor with a decisive influence on the machine’s overall effectiveness. After use, access to the container for cleaning is fast and easy via the mixer lid with motorized lifting mechanism.

1.High-performance cooling with throughput volumes over 2,500 kg/h

2.Can be used for a wide range of different applications e.g. heating, agglomerating, bonding

3.Process-optimized mixing tools guarantee optimum energy input

4.Selection of performance-optimized mixing drives for high energy efficiency

5.Innovative aspiration for optimum dehumidification of the mixture

6.Wide range of optional accessories allows ideal adaptation to installation space requirements

7.Large cooling areas and specifically designed water circulation in container and lid for optimum cooling performance

8.Large lid for easy cleaning access

ChiYu’s combined heating/cooling systems deliver first-class mixing quality and high-volume throughput for the manufacture of a large number of products. The individual requirements and careful processing of raw materials are guaranteed at all times. Our specialists will be glad to advise you on the optimum technology for your product solution.

PVC (hard/soft)

WPC

Master batches

and many more

ChiYu heating/cooling mixer systems can be extended in many different ways by the addition of accessories. Custom-built adaptations can also be developed to your individual specifications in consultation with our experts. Please do not hesitate to contact us for more details.

1.Container weighing

2.Aspiration for heating mixer/jet filter for cooling mixer

3.Injection of plasticizers

4.Container temperature control (external)

5.Hydraulic tool lifting

6.Motorized swivel lid

7.Nitrogen inertization

8.Oxygen concentration measurement

9.Explosion suppression systems

10.Data recording and evaluation

11.Remote maintenance

Our industrial mixers generate perfect mixtures of almost all raw materials. What sounds easy requires many years of experience and sophisticated engineering.

Creating ideal mixtures demands comprehensive knowledge of raw materials. We know the behavior of (almost) any material in the mixing process.

We know how mixing ratio, temperature, pretreatment, tools, mixing duration etc. influence the mixing outcome.

The knowledge of raw materials from various industries flows into the continuous evolution of our mixing technology.

So far we could improve almost every mixing process our customers – try us. Make an appointment for a free mixing advice from our experts.

Minimize Production Time

Maximize Production Output

Reduce Production Costs

Improve Quality of Mixture and Final Products

Maximize Profit

Increase Customer Satisfaction

We offer not only the best mixing technologies but individual solutions for your production process before and after mixing.

Benefit from over 10 years of experience in mixing and production methods.

We analyze your workflow, define requirements and design ideal production workflows.

Together with trusted partners we realize efficient production concepts around your mixing processes.

Our concepts consider quality and efficiency as well as staff-friendly and ergonomic procedures.

Minimizing Production Times

Automating your Processes

Digitalization of Processes

Increasing Output

Optimizing Resources

Increasing Quality of Final Products

Maximizing Profit

Manual Mixing takes too much time due to increasing demand, growing portfolio and new recipes?

Would you like to realize more output, shorter production time and frequent recipe switches?

Our mixers are perfectly suited for starting industrial mixing. ChiYu mixers are easy to handle. They mix a great variety of materials from different industries.

You can mix even the most sensitive raw materials like proteins, aroma, cereals or baked goods.

Reduce mixing-time down to 3-6 min

reduce production costs

one mixer for small to large outputs

flexible output & recipes

always the same quality

integration in process automation

very easy handling